Arc Flash Hazard Analysis

Why Is An Arc Flash Analysis So Essential?

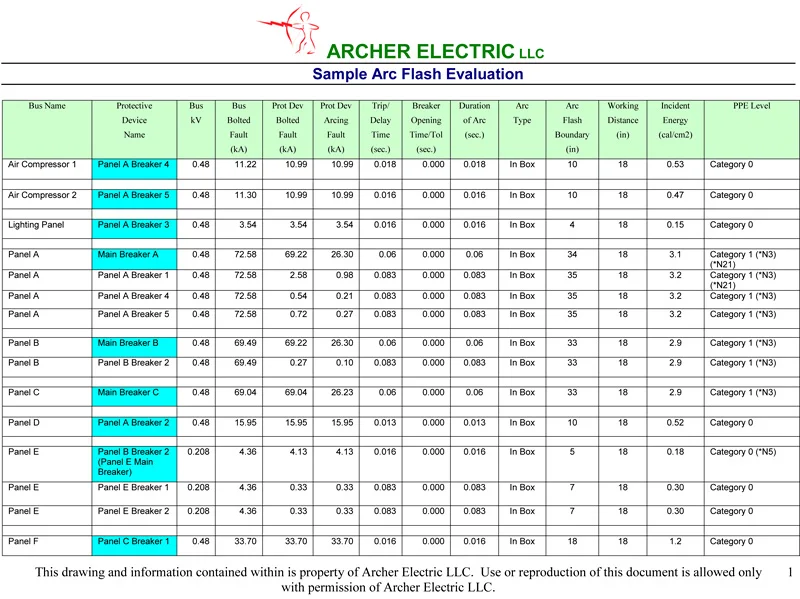

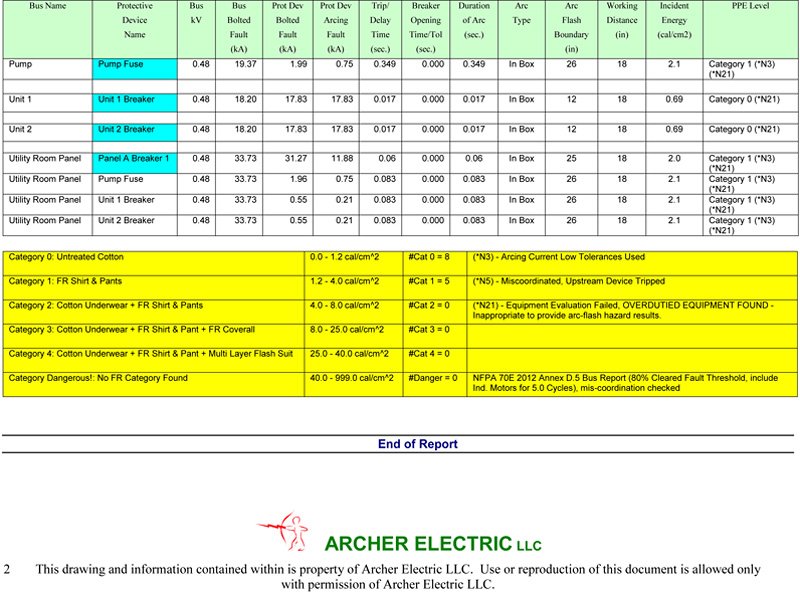

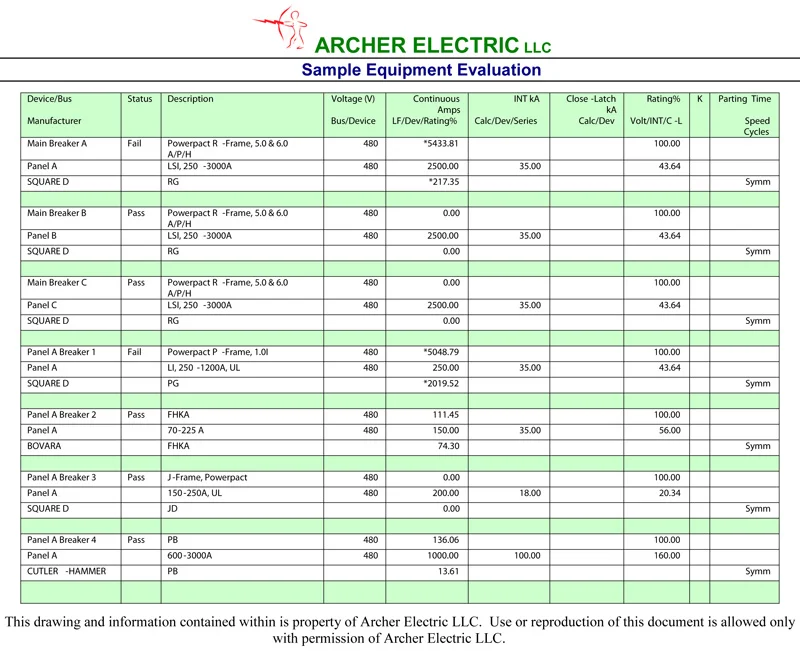

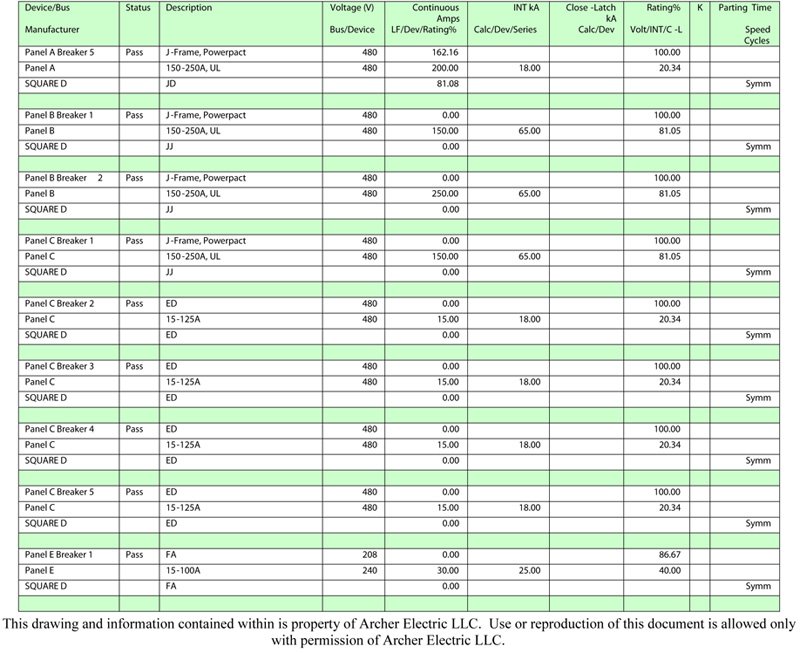

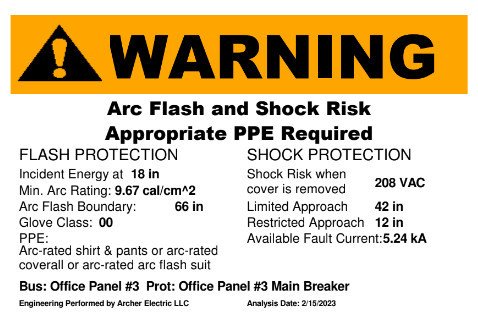

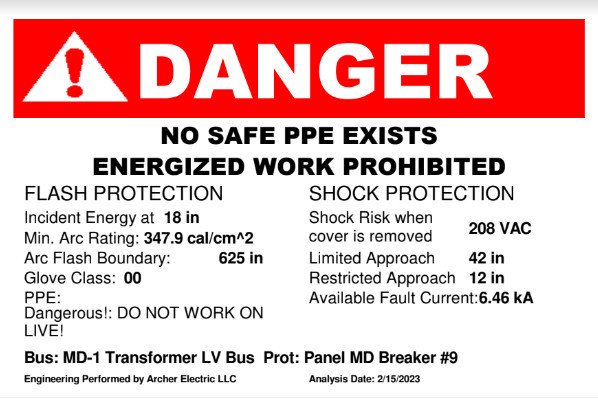

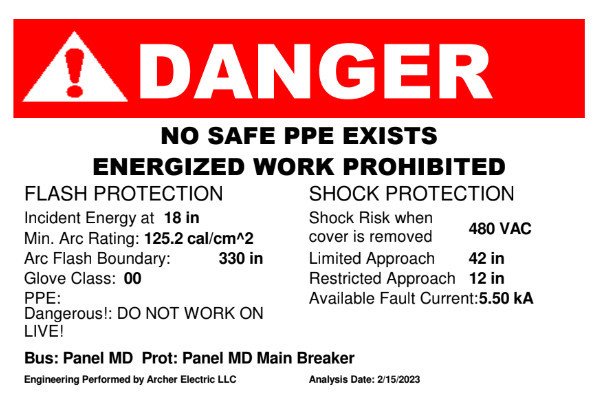

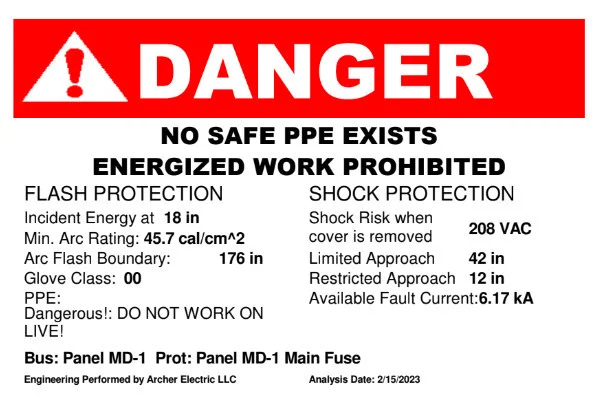

With protection from the dangers of arc flash and arc blast being one of the main focuses of the NFPA 70E, there are few things as important as having a proper and thorough Arc Flash Engineering Study of your facility completed. Not only is it required under OSHA and NFPA 70E regulations, it is what informs your employees and contractors of the danger level associated with testing and working on electrical panels and devices. It also gives individuals who may be performing this testing or work the required information to determine what personal protective equipment (PPE) needs to be worn – the necessary equipment to help protect them from the hazardous situations and often life-threatening burns and injuries that occur as the result of an arc flash incident.

Second degree burns occur at the relatively low incident energy level of just 1.2 calories per centimeter squared, and arc flash incidents are known to kill workers and other unprotected individuals in the area of an incident up to – and beyond – 10 feet away from the source. The Informative Annex K to the NFPA 70E points out that temperatures in a typical arc flash incident can reach 35,000° F and thousands of people are hospitalized or admitted to burn centers each year due to severe burns from arc flash incidents. This is exactly why Wisconsin-based Archer Electric, LLC, urges the use of safe working practices so strongly, always placing equipment in an electrically-safe and de-energized condition before beginning any service or repair, and ALWAYS wearing the appropriate level of PPE for a given task or piece of equipment. The relative danger level of an electrical panel or piece of electrical equipment, expressed as a hazard category, is not something that can be guessed at. This determination of incident energy and related hazard category requires the use of very specific, sophisticated engineering calculations based on numerous component variables that all have to be taken into consideration to accurately generate the available incident energy that any piece of electrical equipment or electrical panel has. This is the main purpose of performing an arc flash hazard analysis engineering study.