Electrical Services

From Panel Tracing and Labeling to Power Systems

Panel Tracing and Labeling

Identify and trace existing circuits to locate and mark accurate feeder/source information, important for both employee safety and compliance with the up-to-date single-line diagram requirements. Panels can also be labeled for lockout/tagout purposes to allow for easy identification of proper points of de-energization for equipment and lighting to know what panels and breakers may need to be locked and/or tagged out before service can be performed.

Electrical Equipment Integration & Upgrades

Have an electrical system or processing component that you would like changed to be more user-friendly, more energy-efficient, or just plain safer? Let Archer Electric work with you to engineer a cost-effective and creative solution. Archer Electric has experience rebuilding, retrofitting, and upgrading existing electrical equipment, as well as integrating new technology, new components, and new system elements to existing machines and production lines

Power Delivery System Analysis, Infared Plant System Studies & Troubleshooting

Often, issues with the power delivery system in a facility can lead to numerous problems related to energy loss and wasted power, and subsequently, a great deal of money wasted on lost or unrealized power. This can be due to load imbalance, problems with a transformer or main service board, or faults in conductors. Wisconsin-based Archer Electric can identify and isolate these issues through cable tracing and testing, locating conductor faults, and advanced metering services of your power delivery system. We work from transformers and your main service down to the individual machines or components in your manufacturing or processing line equipment. For additional capabilities regarding related issues, read more about our Engineering Services.

Maintenance & Preventive Maintenance Programs

Archer Electric can develop both routine and preventive maintenance programs for your electrical systems. Programs include: inspecting equipment grounding points for torque and corrosion; IR testing of panels and equipment; real-time temperature monitoring on loaded and operating equipment; testing and inspecting transformers; and visually inspecting buss bars and bolting points for main service boards, switchgears, and all types of incoming LV and HV yard equipment.

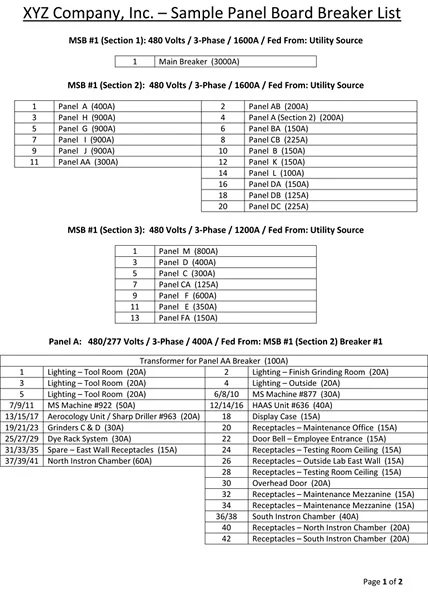

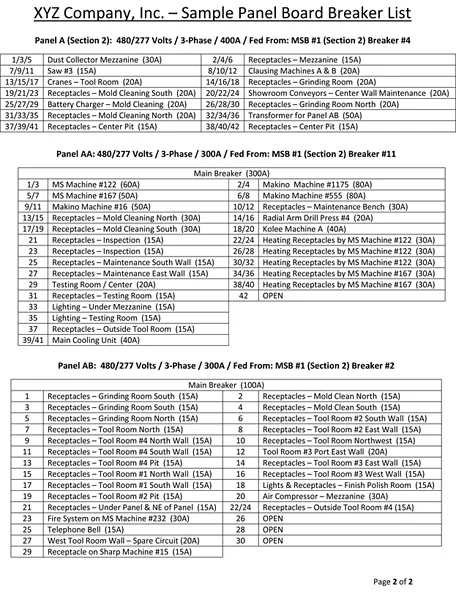

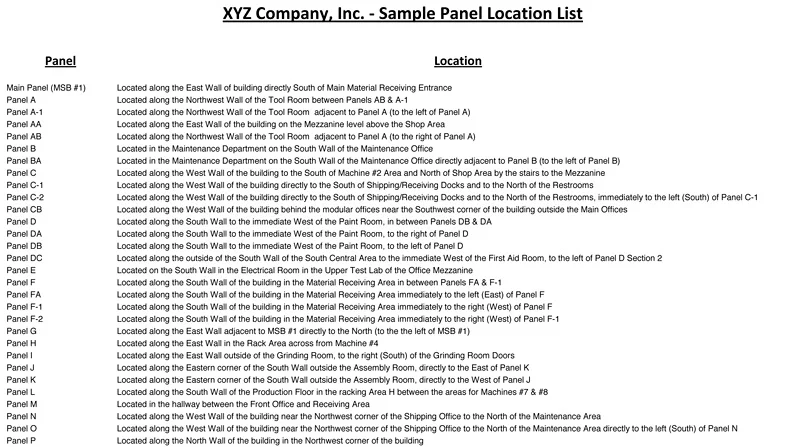

Panel Schedules

Archer Electric can develop a comprehensive database of your electrical distribution system and associated panels, either 3-phase, single-phase, or both. Panel schedules list panel names, electrical source, panel voltage, and a complete list of breaker designations as well as breaker size for easy referencing of each analyzed panel. This comprehensive report is presented in both a printed and digital format to allow for easy updating by your facility’s staff, as revisions are needed. A second report that lists panel locations is generated and included in the final panel schedule report. As part of this service, Archer Electric can also list panel locations on a facility drafted D-size drawing to allow your engineering/drafting staff to add these locations to existing equipment and facility layout drawings.